Toy Safety Test: Impact Test

Toy Safety Test: Impact Test

As a toy manufacturer, you want your products to be successful in the market and recognized by the market, so safety and quality are always the first guarantee.

In order to make the toys on the shelf safe to sell, toy testing instruments are essential to check whether the safety performance of toys meets export standards in production.

Today Hust Tony Instruments will introduce about toy impact testing: Impact Test

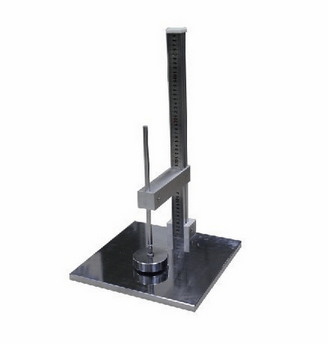

Impact Test Instrument: children’s toy tester,EN Impact Test Table TW-201-EN 71-Toy Test-Manufactuer-Hust Tony

The EN impact test bench simulates the misuse impact test of toy materials or imitation protective device toys.Results are obtained after checking the impact on small parts, dangerous sharp edges, dangerous sharp points or drive mechanisms.

EN Impact Test Table TW-201-EN 71-Toy Test-Manufactuer-Hust Tony

Standards

EN71-1-2014+A1-2018

ISO 8124-1 : 2018

ASTM F963-2017

Application Industry

All kinds of electric ride-on toys can be tested by the EN Impact Test Table.

Falling Ball Impact Test

Falling Ball Impact Tester: This instrument is used to test the impact resistance of all rigid toys covering the face, such as goggles, space helmets or face shields.

According to the standard, after testing, the toy must not produce sharp edges, sharp spots or loose parts that may enter the eye. This applies to toys with cut eye holes, as well as items that cover the eyes.

Toy Ball Impact Tester TW-262A-Manufactuer-Hust Tony

Standards

ASTM F 963 section 8.7.4

ISO 8124-1 section 5.14

GB6675-2 section 5.14

Application Industry

All rigid toys that cover the face can be tested on the Toy Ball Impact Tester TW-262A