Scooter Dynamic Strength Testing Machine TL-011-Supplier-HUST TONY

Scooter Dynamic Strength Testing Machine TL-011

Scooter dynamic strength testing machine is a kind of equipment used to test the strength and reliability of scooters.

It helps manufacturers and designers evaluate the durability of scooters in different situations by simulating dynamic loads under real-world usage conditions.

Meeting Standards

EN 13843:2009, EN 13613:2009, EN 14619:2019 and other standards.

Youtube video :Click here

Technical Specifications

Model | TL-011 |

Drum Diameter | 700mm±10mm |

Drum Speed | 0.5m/s±5% |

Load | 20-100KG adjustable |

Test Time | 1min-99h |

Control System | PLC touch screen controller |

Measurement Accuracy | Speed ±1km/h, load ±1kg, time error accuracy 0.1s |

Power Source | The motor control system is equipped with fixtures: 90° fixtures 70° fixtures |

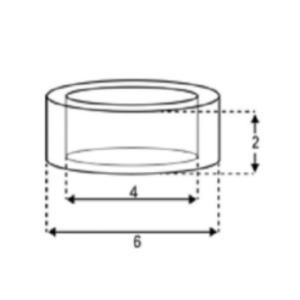

Stumbling Block | Steel, trapezoidal, size according to EN13843:2009, EN 13613:2009, EN 14619:2019 and other standards |

Shutdown Mode | Stop when the number of tests is reached, stop when the equipment is damaged or the amount of deformation is too large, automatically stop and alarm |

Add Weight | Scooter durability kit |

Power Supply | 220V |

Size of Machine (L × W × H) | 3800 × 1500 × 1900mm |

Net Weight | About 600kg |

Instrument Characteristics

1. PLC automatic control, through the touch screen can observe all test data.

2. Can accurately record and test the situation in real time, detect the running time, and the cumulative number of times; With touch screen control, all operations can be operated intuitively on the touch screen.

3. The use of special control software can realize multi-channel closed-loop control to complete the test of automatic control, automatic measurement and other functions.

4. The number of tests can be set, and the equipment will automatically stop and alarm after the detection is completed.

5. With stop/power off memory and breakpoint detection and shutdown function; After a sudden power failure, call again, the device can automatically save the data, and run according to the parameters set before the power failure, without the need to manually boot to set the parameters.

6. Shutdown mode: stop when the number of tests is reached, stop when the equipment is damaged or the amount of deformation is too large, automatically stop and alarm.

7. The equipment has a fault self-diagnosis system, and the equipment fault is automatically diagnosed and the fault code is displayed, which is convenient for checking and troubleshooting.

Standards

EN 13843:2009, EN 13613:2009, EN 14619:2019 and other standards.

Related Products

-

Other Toy Test Templates

EN 71 Feeler Gauge TW-711-EN71-1-Toy Test-Manufacturer-HUST TONY

Read moreRated 0 out of 5 -

Other Toy Test Templates

Simulates Projectiles TW-282-Manufacturer-HUST TONY

Read moreRated 0 out of 5 -

Other Toy Test Templates

Expanding Toy Test Template TW-320-Manufacturer-HUST TONY

Read moreRated 0 out of 5 -

Toys safety testing equipment

Hand Held Metal Detector TW-253-Manufacturer-HUST TONY

Read moreRated 0 out of 5 -

Other Toy Test Templates

Overload Test Loads TW-268D-For Ride-On Toys And Seats-Manufacturer-HUST TONY

Read moreRated 0 out of 5 -

Other Toy Test Templates

Static Strength Weights TW-268A-Manufacturer-HUST TONY

Read moreRated 0 out of 5