Mattress Rollator Tester TNJ-007-Manufacturer-HUST TONY

Mattress Rollator Tester TNJ-007

Mattress Rollator Tester TNJ-007 has been manufactured to

determine the durability of any type of mattress and box

spring unit, regardless of the materials of construction, by

simulating long-term use conditions.

Youtube video : Click here

Mattress Rollator Tester TNJ-007 is suitable to all kinds spring soft mattress. Palm fiber mattress and soft foam mattresses and other polymeric materials reference to the relevant standards. This machine is suitable for mattress.

Test Items: include the following tests and measurement projects

1.Durability test for the bed surface.( simulating the effects to the mattress after the body of people rolls on it)

2.Durability test for bed edge . ( simulate a people sits on the edge of the mattress)

3.Height measurement of the mattress.–thickness test

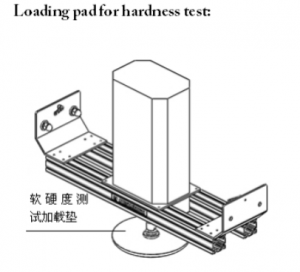

4.Measurement of the Hardness value.—hardness test

Equipment Characteristics

(1) Durability Test Applications& Test Purpose

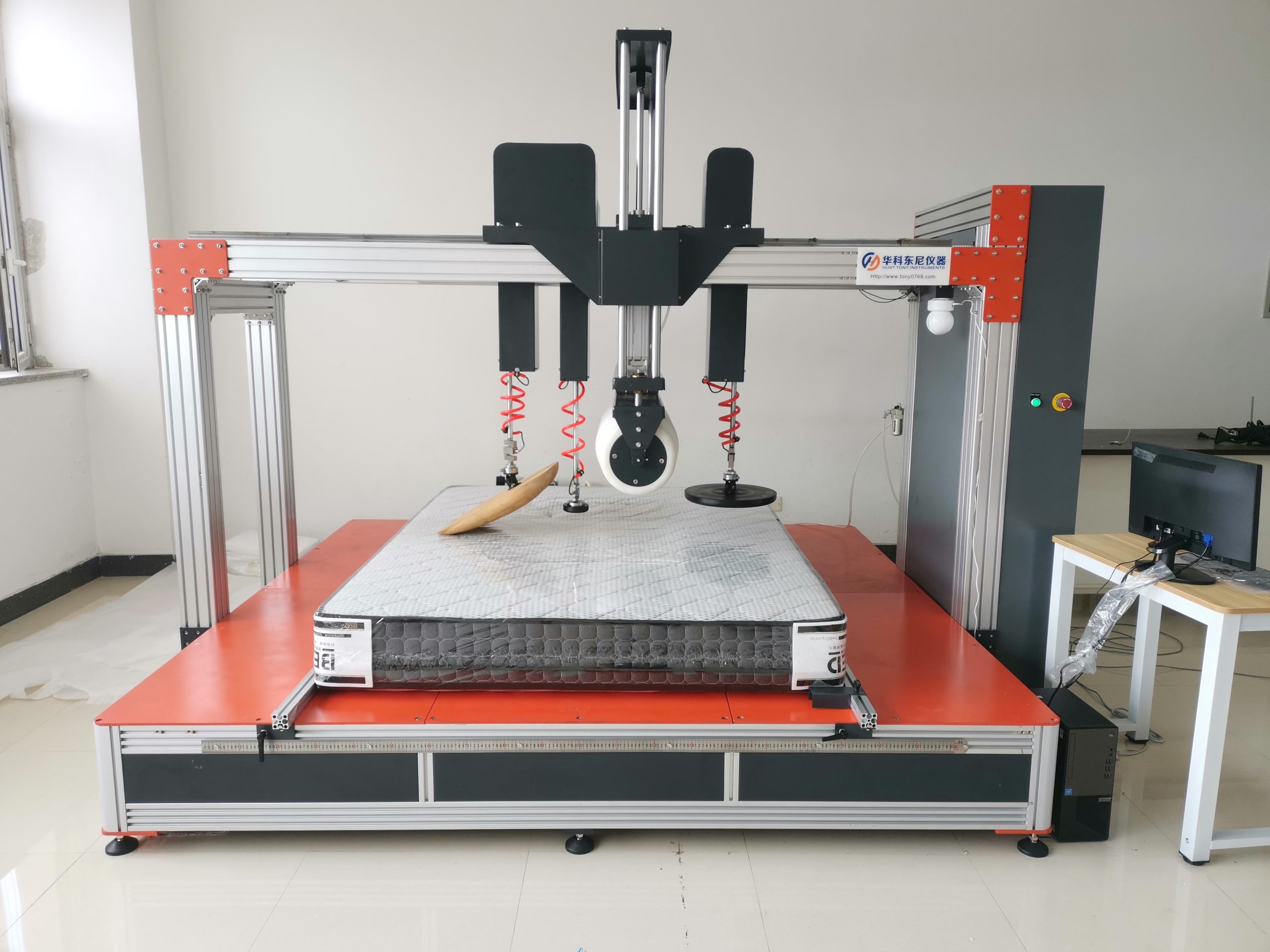

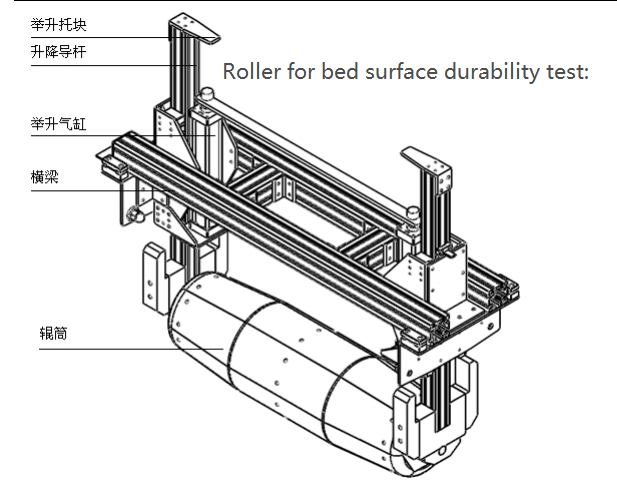

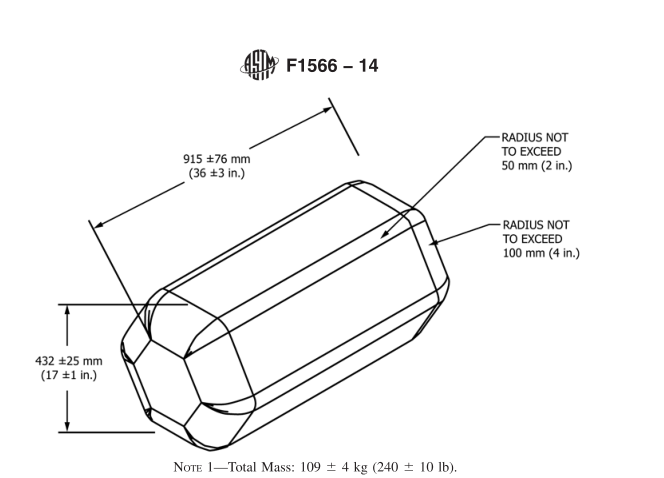

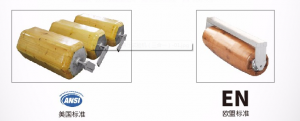

Mattess Durability Tester using a horizontal hexagonal wooden drum roll or cylinder (both ends of the diameter of 250 mm, the middle part of the 300 mm, rolling back and forth on the mattress, simulate human motion to assess the durability of the mattress.

Roller for bed surface durability test:

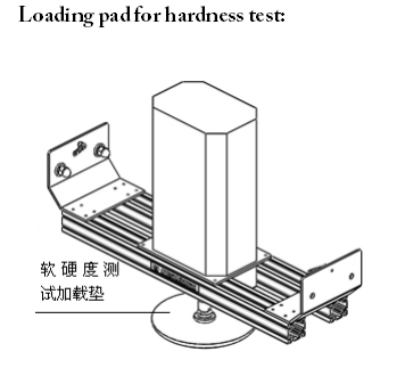

(2) EN Hardness and Height Change Test

Mattress Hardness and Height Change Test Applications & Test Purpose:

The mattress test machine combines the loading device (roll) with a hardness measuring device. Thus, firmness test can be carried out according to ASTM F 1566 or EN 1957, without the need for a rearrangement of the specimen, which would falsify the measured values. It can also display height change by servo measuring system.

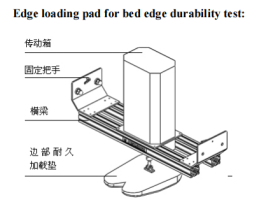

(3) Edge Test

Test Standard: EN1725

Applications& Test Purpose:

The machine increases mattress fatigue test function, it simulate human sitting on the edge of mattress,

with 1000N force to test the fatigue of mattress for 5000 cyclic according to EN1725.

Technical Specifications

Electrical Parameter

| Name

| Function

| Brand

| Detailed Parameters

|

PLC | Programmable Controllers | Siemens | ||

4AD module / 4DA module | Digital-to-analog conversion input/output | Siemens | ||

control system | Execute automatic control program | HUST TONY | ||

Force sensor | Real-time force detection | Hua Lanhai | High-precision force sensor, real-time acquisition of force value signal | |

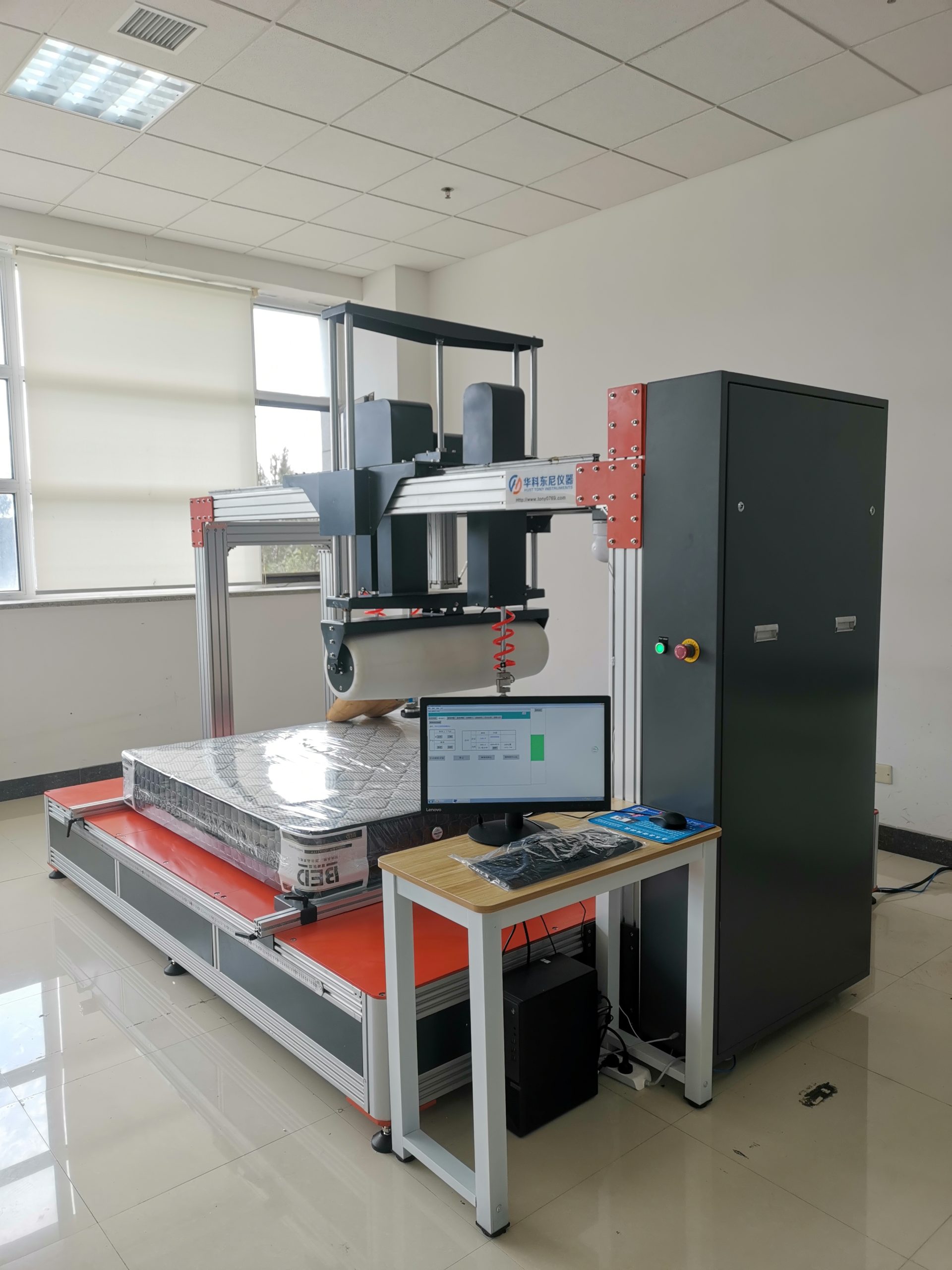

Computer display | Monitoring and parameter settings | Lenovo | ||

cylinder | For drum rise and down | AirTAC | Cylinder diameter * itinerary:80mm*400mm | |

Cylinder magnetic switch | Provide limit protection | AirTAC | ||

servo motor | Used to control displacement and provide load force | delta | accuracy ±0.5mm | |

counter | 0~999999 Can be set | |||

Product Parameter

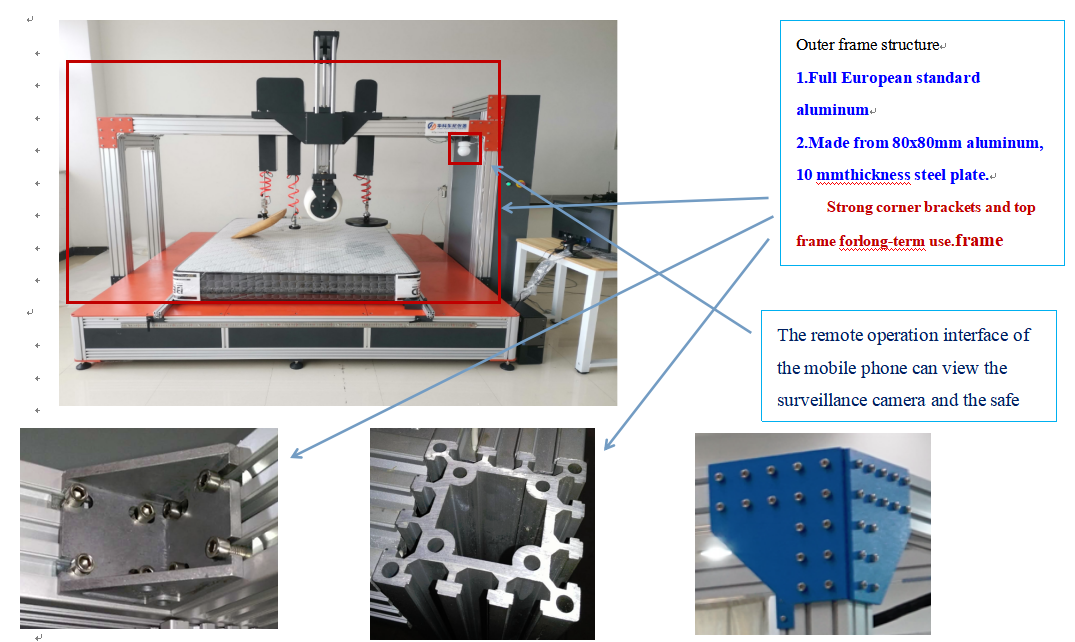

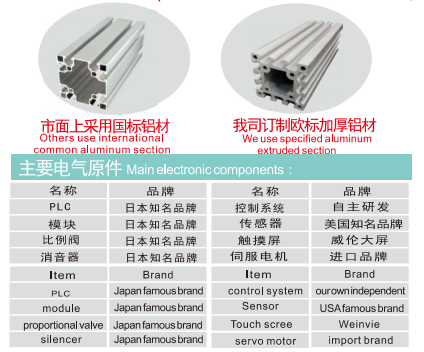

| Instrument size (length * width * height))mm | 2800mmx2100mmx1800mm It is made of 80x80mm European standard aluminum profile | ||

Measurable sample size / minimum / max | Length: 200mm- -2000mm width: 200mm- -2000mm height: 10mm- -400mm Can be customized according to customer requirements | |||

Rolling pressure test speed | For 16 ± 2 cycles / min(or specified by customer) | |||

Roller weight | 1400N±7N | |||

Counter | 0~999999can be set. | |||

Loading cushion on the edge | buttocks shape, 380mmx 495mm | |||

Capacity of force sensor | 2kN | |||

power | AC 220V 10A 50Hz AC 220V 50Hz 3KW | |||

The control way of rolling | Touch screen + PLC control((In addition, you can choose computer control, if customers need it, we will equip it with a computer) | |||

air supply | 6kgf / cm ^ 2 or above (customer provided) | |||

weight | 1200kg | |||

package | wooden case | |||

Transportation requirements | Due to its large size, this equipment needs to be disassembled after transported and needs to be reassembled in use | |||

Standard Configure | 1 host, 1 control box, 1 wire, 1 set of inner hexagon tools, 1 copy of operation manual Trachea 5 meters (one piece) | |||

Features

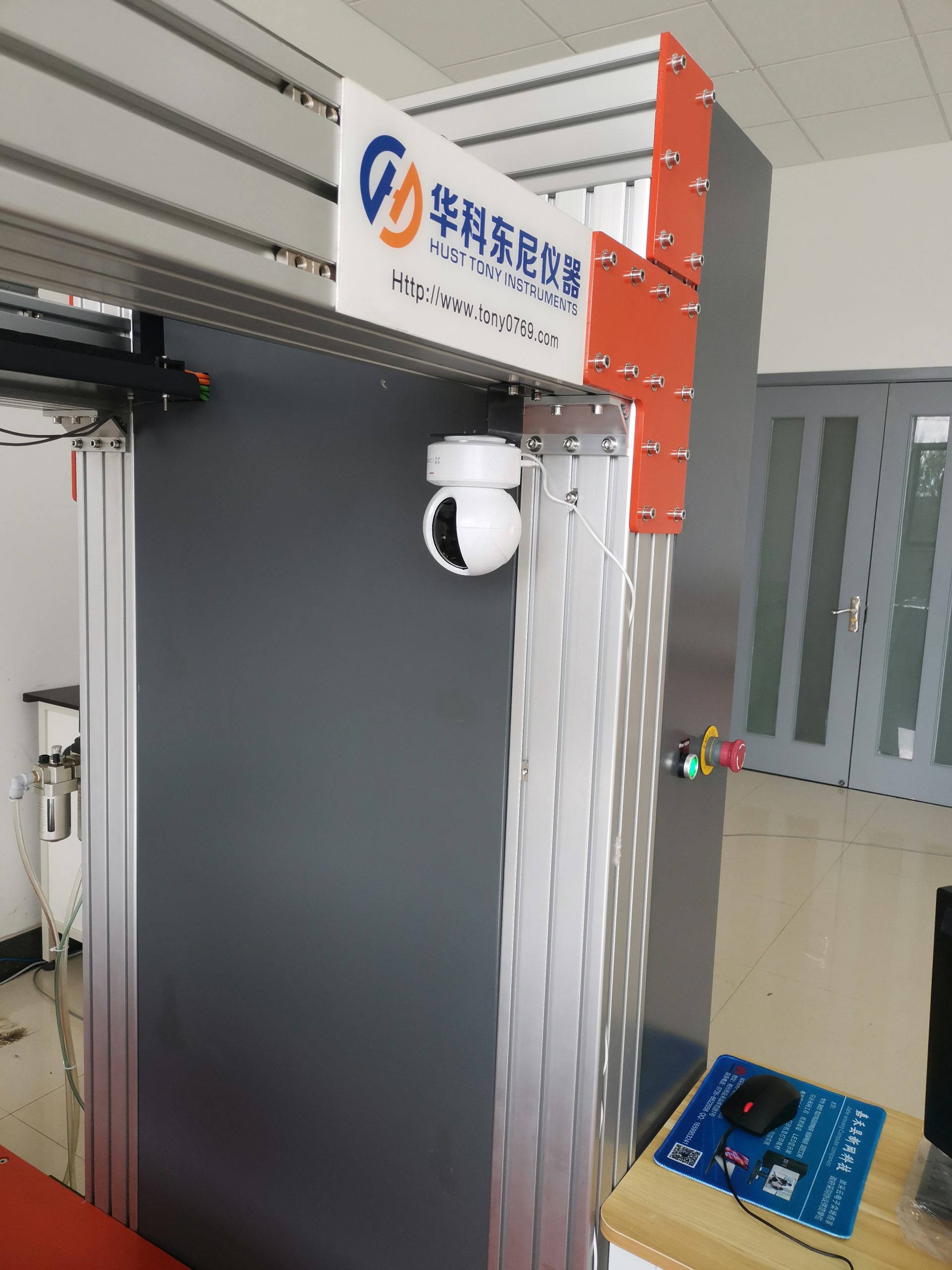

- 1.Novel design, highly integrated, advanced control.

- 2.The test and measurement items that previously required three machines can be completed with one instrument, and the advanced control system and optimized structure make the operation more reliable and the test data more accurate.

- 3.The main frame is made of high-strength industrial aluminum profiles, combined with sheet metal parts treated by advanced electrostatic powder spraying and baking paint technology, the appearance is elegant and beautiful, and the sense of technology is full.

- 4.The built-in sample provides a safer testing process and prevents accidental damage to the machine.

- 5.Multi-point distribution of emergency brake switches, no matter where the operator is, it is convenient to stop the machine in an emergency.

- Pad surface durability test:

- 6.Adopting an independent control system, PLC control alone, combined with a computer display screen, the operation is easy and intuitive, the test process and operating status are clear at a glance, and the number of tests can be set arbitrarily.

- 7.The unique lifting device is convenient to lift the heavy roller before the test, so as to move it to the mattress testing area, and then lower the roller to fully load its own weight on the mattress surface.

- 8.The roller group can move up and down freely during the test to adapt to various uneven conditions on the mattress surface.

- 9.Using advanced photoelectric sensing technology, the starting position of the center line of the mat surface is automatically returned to the original position, the stroke points at both ends are automatically sensed, and the position of the parking area is sensed.

Main Features

- 1.Our equipment is controlled by computer, mobile phone control, Internet control, and real-time video monitoring

- 2.The operating software comes with a test standard program that meets the requirements, and can be upgraded remotely; the test process can be monitored by no one, and the fault can be automatically alarmed, and the fault can be removed remotely; the remote operation interface of the mobile phone can view the surveillance camera and the safe environment of the laboratory site

- 3.Multifunctional interface control software, which can control and monitor multiple devices.

- 4.The control software needs to save the test data of the instrument to the

- database, which can permanently save and query the historical test data.

- 5.The laboratory management system can be connected to the computer database on the equipment to facilitate the management of laboratory equipment and data query and filing

- 6.When no one is in the laboratory, you can enter the device operating system to operate the device through the computer website, QR code, mobile APP, WeChat,

- 7.If the same operating system is compatible and incorporated into one site to operate the device

- 8.European standard aluminum profile (thickened)

Standards

ASTM F1566

BS EN1957

QB/T 1952.2-2011

(Other test standards can be made according to customer requirements)

Related Products

-

Furniture Testing Equipment

Furniture Horizontal Swing Pendulum Impact Tester TNJ-021-Supplier-HUST TONY

Read moreRated 0 out of 5 -

Furniture Testing Equipment

Drawer Durability Strength Testing Machine TNJ-005A-Manufacturer-HUST TONY

Read moreRated 0 out of 5 -

Furniture Testing Equipment

Chair Front Stability Testing Machine TNJ-023-Supplier-HUST TONY

Read moreRated 0 out of 5 -

Tables and Chairs Testing Machine

Chair Seat Rotating Testing Machine TNJ-020-Supplier-HUST TONY

Read moreRated 0 out of 5 -

Tables and Chairs Testing Machine

Chair Seat Drop Impact Durability Tester TNJ-019-Manufacturer-HUST TONY

Read moreRated 0 out of 5 -

Furniture Testing Equipment

Chair Armrest Durability Test Machine TNJ-018-Manufacturer-HUST TONY

Read moreRated 0 out of 5 -

Furniture Testing Equipment

Chair Seating and Back Testing Machine-TNJ-017-Manufacturer-HUST TONY

Read moreRated 0 out of 5 -

Furniture Testing Equipment

Chair Backrest Durability Testing Machine TNJ-006-Manufacturer-HUST TONY

Read moreRated 0 out of 5