IP Dust Test Chamber WT-14-For Environmental Testing-Manufacturer-HUST TONY

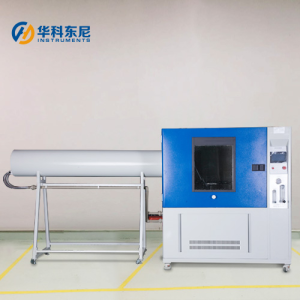

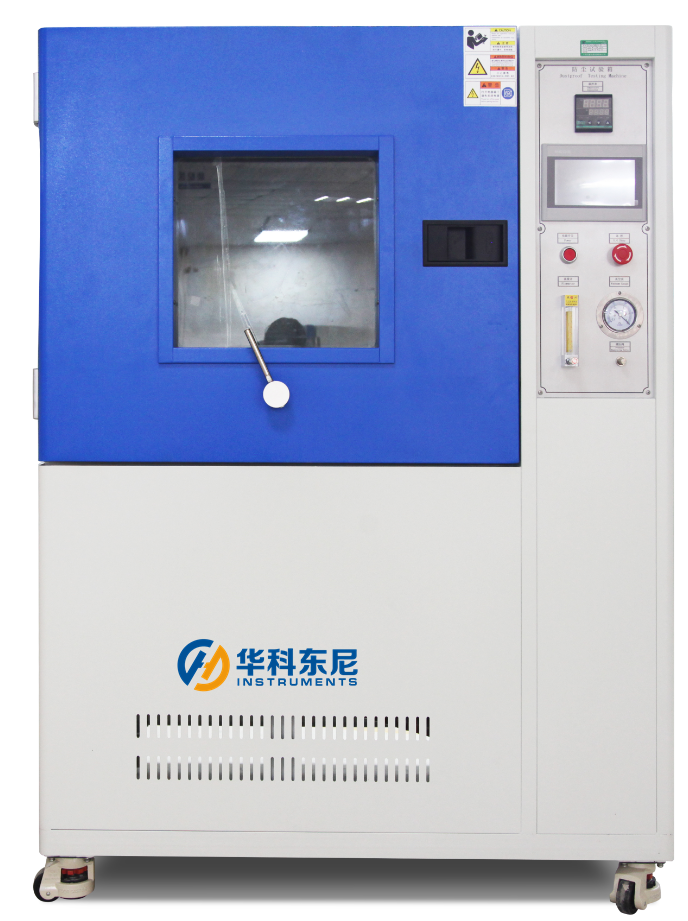

IP Dust Test Chamber WT-14

IP Dust Test Chamber is used for testing for the physical and other related properties of the products under the simulated dust climate conditions, such as electronic and electrical products, lamps, cabinets, electrical components, automobiles, motorcycles and their parts.

IEC60529:1989 +A1:1999 +A2:2013

GB/T4208-2017 : 13.4, 13.5 and picture 3

GB7000.1 : 9.2.1,9.2.2 and picture 6.

Technical Specifications

Model | WT-14 |

The Size Outside The Water Tank | 1250*1020*1755 mm (include casters) |

The Size of The Inner Box | 800*800*800 mm |

Wire Diameter of Metal Net | 50 um |

Useful Volume (L) | 500 L |

Wire Interval | 75 um |

Talcum Powder Dosage | 2~4kg/m |

Dust For Testing | Dry talcum powder |

The Way to Spray Dust | Free dust |

Total Test Time | 1S-999Hours (adjustable) |

Vibration Time | 1S -999Hours (adjustable) |

Iming Accuracy | +1S |

Vacuum | 010Kpa (adjustable) |

Pumping Speed | 0-60L/H (adjustable) |

This Tester Chamber Voltage | 220V,50Hz |

Sample Voltage | 220V.50Hz |

Power | 1.5 kw .Fire linetzero linetprotectivene(Resistance 40) |

Accessories:

Dry talcum powder 1 bag (approx. 2KG)

Features

1. Suitable for product IP5X and IP6X dusttesting.

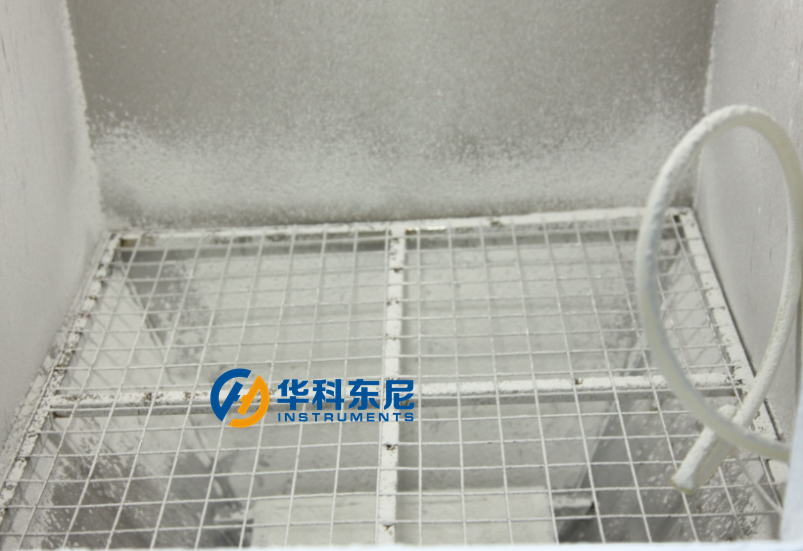

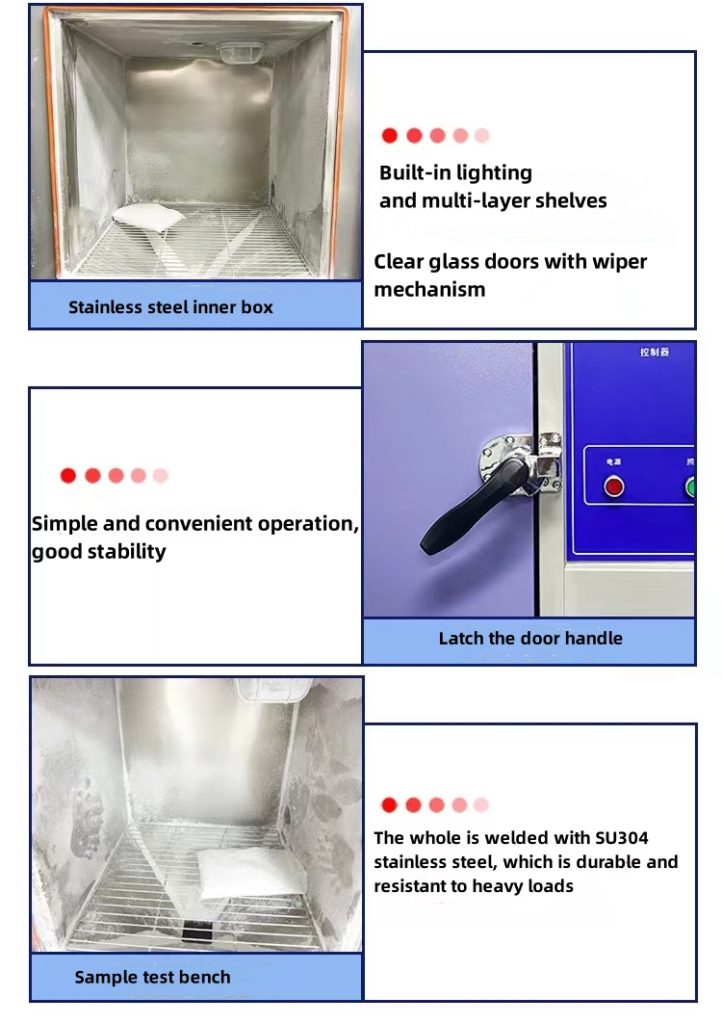

2. The inner box and turntable are all made of SUS304 stainless steel plate.

3. The housing is made from Chinese high-quality steel plate.

4. Special silicone seal ring, good elasticity, good durability.

5. The bottom of the device has replaceable dust components that make it easy to replace used dust.

6. Built in vibratory device ,it can be operated automatically alternately to prevent dust from sticking to the wall of the box and condensation.

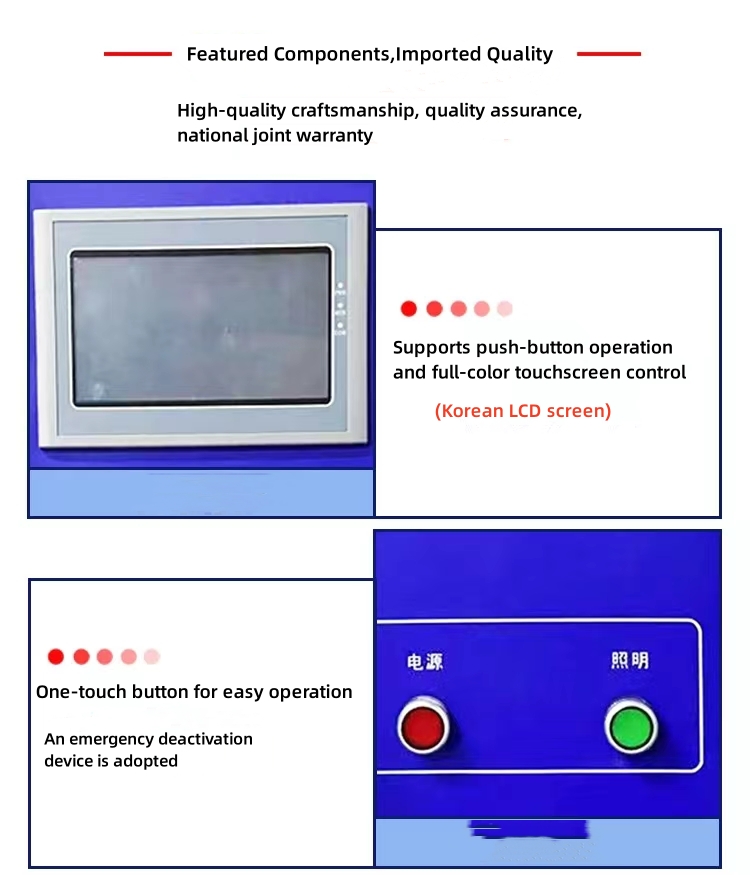

7. The observation window is made of tempered glass and built a LED lights for easy observation of internal testing.

8. There is a pumping tube in the box, the sample can be vacuumed (samples need to be reserved for breathing holes).

9. 7 inch touch screen and Panasonic PLC , The system controls the dust blower, dust vibration and test time.

10. Heating system: The circulating dudesis built in a heater to avoid dust condensation.

11. Vacuum system: Pressure gauge, air filter, Pressure regulating FRL, connecting pipe, Vacuum pump.

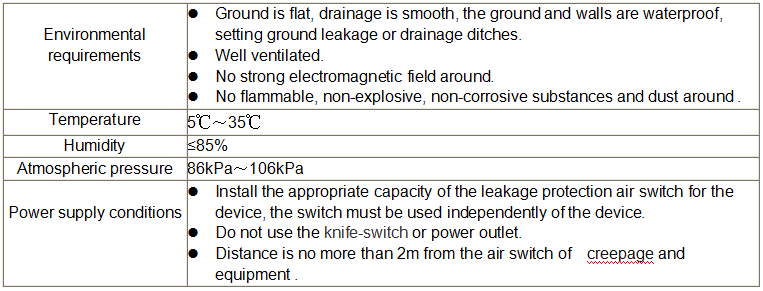

Terms of Use

Standards

IEC60529:1989 +A1:1999 +A2:2013

GB/T4208-2017 : 13.4, 13.5 and picture 3

GB7000.1 : 9.2.1,9.2.2 and picture 6.

Application Area

Related Products

-

Other Lab Testing Equipment

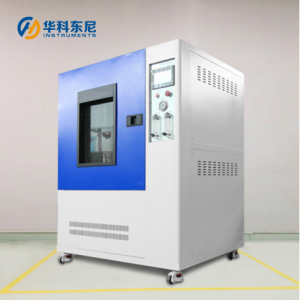

IPX5 IPX6 Strong Jet Water Test Chamber WT-07-Waterproof Test-Supplier

Read moreRated 0 out of 5 -

Other Lab Testing Equipment

IPx5 IPx6 Water Jetting Test Chamber WT-06-Manufacturer

Read moreRated 0 out of 5 -

Other Lab Testing Equipment

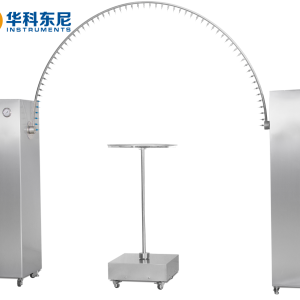

IPX3/4 Oscillating Tube Test Device WT-04-Supplier

Read moreRated 0 out of 5 -

Other Lab Testing Equipment

IPX3 IPX4 Oscillating Tubes Rain Tester WT-05-Direct Manufacturer

Read moreRated 0 out of 5 -

Other Lab Testing Equipment

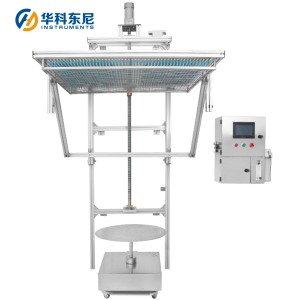

IPX1 IPX2 Drip Rain Test Chamber WT-02-Drip Test-Instrument Manufactuer

Read moreRated 0 out of 5 -

Other Lab Testing Equipment

Rain Test Chamber WT-01-Instrument Manufacturer

Read moreRated 0 out of 5