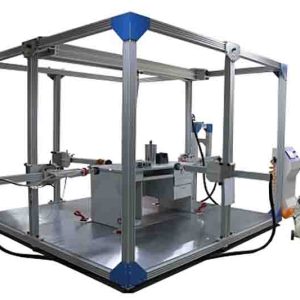

Furniture Comprehensive Testing Equipment TNJ-001-Desk ,Chair,Bed,Cabinet-Manufacturer

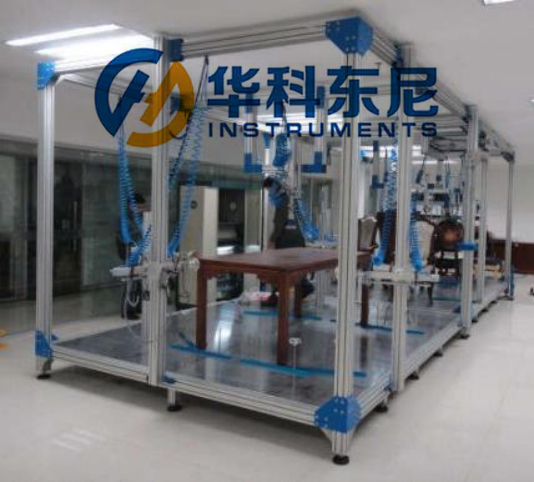

Furniture Comprehensive Testing Equipment

Furniture Comprehensive Testing Equipment – Desk , Chair , Bed,Cabinet TNJ-001 is based on BIFMA X5.1, BIFMA X5.4 & BIFMA X5.9,ect

-Chair – vertical backrest, tablet, foot rest, arm durability for multi seating, structural durability

-Cabinet- leg/glide assembly strength test

Youtube video : Click here

How Does The Furniture Testing Machine Work ?

To learn more about how it works, Furniture Comprehensive Testing Equipment TNJ-001,please click this link

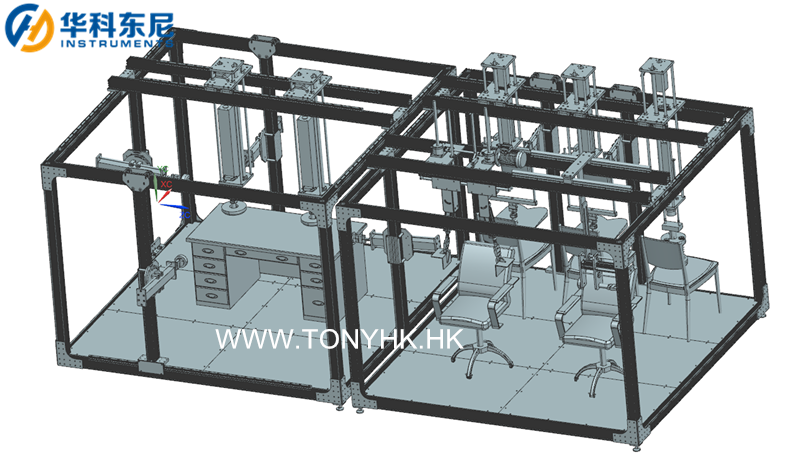

The Composition of The Equipment

1.The control system can meet 12 cylinders work at the same time. Each of cylinders can work independently. They can also work in a group. For cylinders work in the same group, the operating system can control each cylinder’s operating sequence and the loading time. It means that loading time, holding time and waiting time can be set by computer.

2.If magnetic valve used for electricity distribution, pressure regulating double used for filtering oil and water or position sensor is damaged,the test machine can stop automatically test number:0—999,999.times can be set. It can stop automatically when it reaches the setting number. It can also save the test results automatically if the machine is stopped or the power is interrupted suddenly.

3.Computer + loading form closed-loop force control which is controlled by the program that has been set on the computer(directly set test requirement on the computer, such as force value, shift and so on. Not need adjust the pressure of cylinder and the limit sensor on the cylinder.)Controlled by the computer equipment to run automatically.12 control channels can use force value to control. It is four channels that can not only be controlled by force value, but also shift distance.

4.The computer program can set the force value and the test number of testing. The computer can also display the force value and the test number on its screen directly. When it is broken down, the alarm will ring automatically.

5.If the detected specimen is damaged. The tester stops and saves the testing results. The test report can be edited after the experiment.

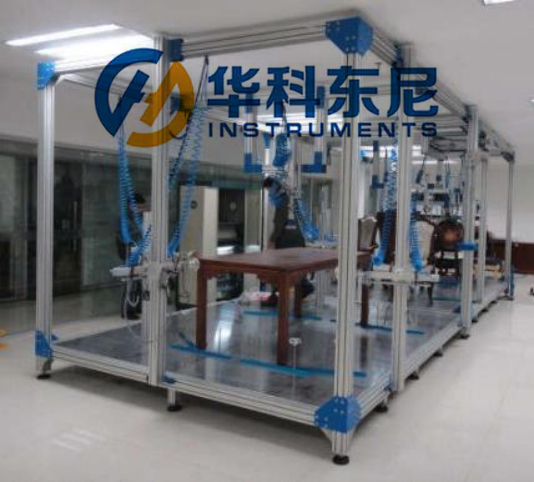

6.Cylinder on the beam or column can be moved horizontally and vertically. The angle of fixed device can be set. Fixed way can choose any force application Angle. The cylinder can rotate 360 degrees and position in the vertical direction of the frame. Don’t need to remove the cylinder’s fixed position when it is rotating.

7.There is no need for people to look after the test. The test experiment can stop testing when it is finished or the specimen is damaged. The machine can also save the test results at the same time.

8.Test system has automatic modulation ability, when using standard weight to adjust the force value, the system can adjust automatically if it occurs deviation. Correction factor and force value can be saved for the same machine at the same time. It is easy to operate because it can call the history of correction.

9.Software can control six channels at the same time; each channel is operated by benchmark synchronization time. This ensures that action and data processing can be synchronous. Different channels divided into groups to control, if there is a sample in a channel is already broken, the associated channels in the same group will stop at the same time, the rest of channels can continue to work.

10.There is no less than 12 scram buttons. The devices can be stopped in each button in emergency circumstances that makes it conveniently

11.Operation Software special design for standards select(this software also could be update for other test standards by remote control), and we will put standard test method and test items into this software, user could select which test item he want for the test, easy and simple.(This function is currently on the market, only we can do it)

Technical Specifications

Electrical parameter | Name | Function | Brand | Detailed parameters |

PLC | Programmable controller | Siemens | ||

4ADmodule /4DAmodule | Digital analog conversion input/output | Siemens | ||

Control system | Perform automatic control procedures | HUST TONY | ||

Force sensor | Real-time detection of force values | Hualan Sea | High-precision force sensor that collects force signals in real time | |

Computer | Monitoring and parameter setting | association | ||

Load the cylinder | Provides load force | AirTAC | ||

Cylinder magnetic switch | Provides limit protection | AirTAC | ||

Proportional valves | Control the cylinder output pressure | SMC | ||

muffler | Eliminates the noise of the cylinder exhaust | SMC | ||

Encoder displacement | Accuracy± 0.5mm | |||

counter | 0~999999 times can be set | |||

Control mode | Computer+PLC control | |||

Product parameter | Instrument size(Long * wide * high)mm | 1000cm * 250cm*210(It can be customized according to customer requirements or product size) | ||

Measurable sample( Table,Cabinet ) size / minimum, max | Measurable dimensions of the table, durability test (Measurable Dimensions): Longest:1900mm Highest:1800mm Widest:1900mm Minimum length and width:500mmx500mm Minimum height:400mm Can be customized according to customer requirements Table Impact Test (Measurable Dimensions): Longest:1900mm Widest:1900mm Highest:1800mm Minimum height:1200mm Minimum length and width:500mmx500mm Can be customized according to customer requirements Cabinet test (measurable size): Highest:1500mm Longest:2000mm Widest:2000mm Can be customized according to customer requirements | |||

Measurable dimensions of the Chair .Measurable sample size / minimum / max | Longest:1600mm Widest:1400mm Highest:700mm Minimum length:400mm Minimum width:300mm Minimum height:100mm Can be customized according to customer requirements Duplex test (two chairs tested at the same time) | |||

Measurable dimensions of the Bed .Measurable sample size / minimum / max | Longest:2000mm Widest:2000mm Highest:1200mm Minimum length:300mm Minimum width:300mm Minimum height:300mm Can be customized according to customer requirements | |||

source | 220 V, 50 Hz | |||

air supply | 6kgf/cm^2or above stable air source | |||

weight | about:1200kg | |||

package | wooden case | |||

Transportation requirements | Due to its large size, this device needs to be disassembled and transported and reassembled at the point of use | |||

Max Capacity | Maximum vertical horizontal: 3000N The maximum force level : 1000N | |||

Loading cylinders | AirTAC | |||

Loading force value (Max) on the theory | 1500Nþ Force value induction: high-precision power sensor | |||

Applied standards: | EN12521-2015 EN12520-2015 EN 1728-2012 EN 1730-2012 BIFMA 5.1-2002 BIFMA X5.4-2012 EN581-2:2015(E),ect (Other test standards can be made according to customer requirements) | |||

Control way | PLC control+computer One computer can control and operate all instruments and test items | |||

Air source | Air supply input is 0.4Mpa-0.8Mpa. (6kgf/cm^2 or above, supplied by customer themselves) | |||

Competitive Features

1.Novel design, highly integrated, advanced control.

2.The test and measurement items that previously required three machines can be completed with one instrument, and the advanced control system and optimized structure make the operation more reliable and the test data more accurate.

3.The main frame is made of high-strength industrial aluminum profiles, combined with sheet metal parts treated by advanced electrostatic powder spraying and baking paint technology, the appearance is elegant and beautiful, and the sense of technology is full.

4.The built-in sample provides a safer testing process and prevents accidental damage to the machine.

5.Multi-point distribution of emergency brake switches, no matter where the operator is, it is convenient to stop the machine in an emergency.

Pad surface durability test:

6.Adopting an independent control system, PLC control alone, combined with a computer display screen, the operation is easy and intuitive, the test process and operating status are clear at a glance, and the number of tests can be set arbitrarily.

7.The unique lifting device is convenient to lift the heavy roller before the test, so as to move it to the mattress testing area, and then lower the roller to fully load its own weight on the mattress surface.

8.The roller group can move up and down freely during the test to adapt to various uneven conditions on the mattress surface.

9.Using advanced photoelectric sensing technology, the starting position of the center line of the mat surface is automatically returned to the original position, the stroke points at both ends are automatically sensed, and the position of the parking area is sensed.

Main Feature:

10.Our equipment ,Furniture Comprehensive Testing Equipment TNJ-001,is controlled by computer, mobile phone control, Internet control, and real-time video monitoring

11.The operating software comes with a test standard program that meets the requirements, and can be upgraded remotely; the test process can be monitored by no one, and the fault can be automatically alarmed, and the fault can be removed remotely; the remote operation interface of the mobile phone can view the surveillance camera and the safe environment of the laboratory site

12.Multifunctional interface control software, which can control and monitor multiple devices.

13.The control software needs to save the test data of the instrument to the database, which can permanently save and query the historical test data.

14.The laboratory management system can be connected to the computer database on the equipment to facilitate the management of laboratory equipment and data query and filing

15.When no one is in the laboratory, you can enter the device operating system to operate the device through the computer website, QR code, mobile APP, WeChat

16.If the same operating system is compatible and incorporated into one site to operate the device

17.European standard aluminum profile (thickened)

18.One computer can control and operate all instruments and test items(A whole instrument can complete the table, cabinet, chair and sofa test at the same time)

Standards

EN12521-2015,EN12520-2015

EN 1728-2012,EN 1730-2012

BIFMA 5.1-2002,BIFMA X5.4-2012

EN581-2:2015(E),ect

(Other test standards can be made according to customer requirements)

Related Products

-

Tables and Chairs Testing Machine

Drawer Durability Testing Machine TNJ-005-Manufacturer-HUST TONY

Read moreRated 0 out of 5 -

Furniture Testing Equipment

Caster and Base Durability Testing Machine TNJ-004-Manufacturer-HUST TONY

Read moreRated 0 out of 5 -

Furniture Testing Equipment

Chair Legs Pressure-Resistant Tester TNJ-003-Manufacturer-HUST TONY

Read moreRated 0 out of 5 -

Furniture Testing Equipment

Strength Durability Furniture Test Equipment TNJ 002-For Table and Bed-Manufacturer

Read moreRated 0 out of 5