Four Point Bending Test Machine HTP-006-Manufacturer-HUST TONY

Four Point Bending Test Machine

Four Point Bending Test Machine is suitable for compressive and bending tests on tablet computers, mobile phone lenses, glass and other products.

It adopts servo motors, ball screws, and American original force sensors; Ideal test equipment for technical supervision departments.

Youtube video :Click here

Equipped with special test control software and clamping device, it can test the performance of the lens, and automatically calculate the maximum test force value (minimum force value/average value) and breaking force value according to GB, JIS, ASTM, DM, ISO and other standards. Tensile and compressive strength, elongation, peel strength, peel force and other parameters, the results are accurate, reliable and repeatable.

It can also carry out data rounding (GB8170), print out Fm, Rm, Rp, ReH, ReL, Re, A, Z, E and other mechanical performance indicators and load-deformation, stress-strain and other curves.

Equipped with special three-point compressive, four-point compressive, and anti-bending jigs; it is an ideal equipment for enterprises and supervisory agencies to test phase difference products and for teaching and research in scientific research institutions.

Technical Specifications

Model | HTP-006 |

Capacity Selection | 10kg,50kg,100kg,200kg,500kg,1000kg,Optional, high-precision load of the American Transli brand |

Accuracy Class | Level 0.5 |

Effective Force Range | 0.4%~100% |

Force Measurement Accuracy | Within ±0.5% of indicated value |

Testing Machine Resolution | The maximum load is 1/±250,000 yards, there is no division between inside and outside, and the resolution remains the same throughout the process |

Load Transducers | Basic configuration: pulling and pressure sensors (maximum load) |

Effective Test Width | 400mm |

Effective Stretching Space | 500mm(without fixture) |

Test Speed Range | 0.05~500mm/min |

Displacement Measurement Accuracy | Within ±0.5% of indicated value |

Test Bench Safety Device | Electronic limit protection |

Test Bench Return Function

| Manual or automatic, automatic or manual return to the initial position of the experiment after the end of the test |

Overload Protection | Above the maximum load by 10%, the machine is automatically protected |

Fixture Configuration | One set of three-point bending fixture |

Host Size | 650×500×1200mm |

Motor | 220V±10% 0.4KW Taiwan TECO servo motor |

Transmission Mechanism | High precision ball screw |

Host Weight | (Approx)120 Kg |

Control Software Introduction

Software Operating System Language | Simplified Chinese/English |

Force Unit | N,KN,Kgf,Lbf |

Unit of Length | mm, cm, in can be freely converted |

Auto Zero | When the computer receives the command to start the test, the measuring system will automatically return to zero |

Display Method | Data and curves are dynamically displayed along with the test process |

Result Reproduction | The test results can be accessed arbitrarily, and the data curve can be re-analyzed |

Comparative Results | Multiple test characteristic curves can be superimposed, reproduced, enlarged, and presented in different colors for analysis and comparison of a group of samples |

Emergency Shutdown | Equipped with an emergency stop switch, which is used to cut off the power of the whole machine in an emergency |

Control Method | |

1. Various control methods such as computer software setting speed, setting load breaking (breaking), running time, etc. | |

2. Automatically determine material breakage, crushing, etc. and automatically stop, and can be set to automatically return | |

Curve Type | |

1. Load-displacement, load-time, displacement-time | |

2. Stress-strain, strain-time, stress-time | |

3. The vertical and horizontal coordinates of the curve can be set arbitrarily | |

Available Test Data | |

1. Maximum strength, minimum strength, breaking value, upper and lower yield strength, tensile strength, compressive strength, elastic modulus, elongation, maximum, minimum, average value of the peeling interval, etc. With overload, overcurrent, overvoltage, undervoltage, overspeed, stroke and other multiple protections | |

2. The data results are exported from the current national standard crystal report format | |

Advantages Of Our Instruments

HUST TONY uses the latest control board for better sample rates.

Main Features

- 1. The main controller adopts the most advanced 32-bit ARM processor in the 21st century, and its processing speed reaches the level of a Pentium-level general-purpose computer. Compared with the traditional 8-bit single-chip microcomputer measurement and control system, the overall performance is greatly improved, the operation speed is faster, and the control accuracy is higher.

- 2. The core device of data acquisition adopts the latest ultra-high-precision 24-bit AD in the United States, and the sampling rate can reach 2000 times per second, which can capture the instantaneous change process of power. And the original 6-point calibration technology is used to further improve the accuracy, and the force measurement accuracy is better than the national 0.5 level (the highest level) standard.

- 3. The counting of the displacement encoder adopts 4 frequency doubling technology, which increases the displacement resolution by 4 times, up to 0.0005mm.

- 4. There are two output control modes of pulse and voltage, which can control any servo motor, variable frequency motor or DC motor with pulse or voltage control interface to achieve smooth stepless speed regulation. In addition, switching signal outputs such as rising, falling and stopping are available. It is used to directly drive external relays or solenoid valves, and can be used to control DC motors or pneumatic, hydraulic and other power devices

- 5. Advanced three closed-loop technology of speed, displacement and force can realize precise arbitrary waveform control

- 6. Rich interface expansion capability: up to 4 channels of 24-bit analog input, 3 channels of 16-bit analog output, 3 channels of pulse output, 3 channels of AB phase photoelectric encoder input, 9 channels of digital input, 8 channels of digital output, 1 USB interface, 1 RS232 interface, 1 RS485 interface, 4 LCD interfaces, 1 parallel micro-printer interface, 1 serial micro-printer interface, 1 8×4 matrix keyboard interface

- 7. All input and output interfaces adopt high-speed photoelectric isolation technology, which has strong anti-interference ability!

HUST TONY adopts Taiwan TBI ball screw for better transmission accuracy.

Main Features

- 1. High transmission efficiency The transmission efficiency of the ball screw pair is as high as 90% to 98%, which is 2 to 4 times that of the sliding screw pair, and can efficiently convert torque into thrust. Sensitive and stable transmission, small frictional resistance, good sensitivity, no vibration when starting, no crawling at low speed, micro-feeding can be controlled at μ level.

- 2. High positioning accuracy The temperature rise is small during the transmission process of the ball screw pair, the axial play and primary elastic deformation can be eliminated by preloading, and the screw can be pre-stretched to compensate for thermal elongation, so high positioning accuracy and Repeatability.

- 3. Good precision retention, accurate raceway shape, minimal rolling friction and wear, good precision retention, reliability and service life.

- 4. Good precision retention, accurate raceway shape, minimal rolling friction and wear, good precision retention, reliability and service life.

- 5. Good synchronous performance The ball screw has the characteristics of high lead accuracy and good sensitivity.

HUST TONY adopt Japanese Tamagawa servo drive to better ensure correctness.

Main Features

The output power of Panasonic AC servo motors is generally 0.1-100 W, and the power frequency is divided into 50Hz, 400Hz and other types. It is widely used, such as in various automatic control, automatic recording and other systems.

High speed and high response Speed response frequency up to 1kHz; high-performance mechanical adaptability Can receive pulse commands up to 2Mpps Built-in instantaneous speed observer, which can detect the motor speed quickly and with high resolution

Ultra-low vibration

- 1. Adaptive filter, which can automatically adjust the notch filter frequency according to the different mechanical resonance frequencies

- 2. Two manual notch filters to suppress mechanical resonance

- 3. Two-channel vibration suppression filter to suppress vibration at the remote end of the machine. The global environment concerns and corresponds to the ROHS directive, using lead-free solder

Miniaturized design

- 1. Miniaturization achieved by optimal thermal analysis of the driver, 75% in volume and 80% in weight compared to the past

- 2. Using the new punching process of thin die steel plate, the iron loss is greatly reduced, the length of the motor is shortened (70% in the past) and the driver model is reduced

Advantage:

- 1. Good speed control characteristics, smooth control can be realized in the whole speed range, almost no oscillation;

- 2. High efficiency, more than 90%, no heat; high speed control;

- 3. High precision position control;

- 4. Realize constant torque and low noise in the rated operating area;

- 5. No brush wear, maintenance-free;

- 6. No wear particles, no sparks, suitable for dust-free and violent environments

HUST TONY adopt professional processing technology to better ensure quality.

Main Features

- 1. Precise processing technology ensures the cooperation of the beam, bearing and screw, reduces the error caused by processing, and further ensures the accuracy.

- 2. The fuselage is treated with plastic spraying, and the fixtures are equipped with regular heat treatment process, which is durable and orthodox in appearance.

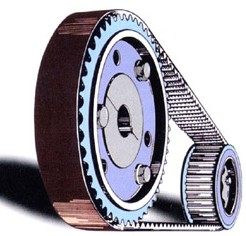

- 3. The transmission mechanism in the bottom box of the whole machine is synchronous belt transmission. Compared with friction belt transmission, there is no relative slip between the pulley and transmission belt of synchronous belt transmission, which can ensure a strict transmission ratio. However, synchronous belt drives have higher requirements on center distance and dimensional stability.

- 4. Synchronous belt drive has the advantages of belt drive, chain drive and gear drive. Synchronous belt transmission Since the belt and the pulley rely on meshing to transmit motion and power, there is no relative slip between the belt and the pulley, which can ensure an accurate transmission ratio.

- 5. Full computer testing machine measurement and control system.

Four Point Bending Test Machine HTP-006-HUST TONY

This measurement and control system is specially developed for tensile machines, presses, and electronic universal material testing machines.

It is suitable for measuring the mechanical properties and related physical parameters of various materials under tension, compression, bending, shearing, tearing, peeling, puncture and other states.

Can be used for tension, compression, three-point bending, four-point bending, shearing, tearing, peeling, puncture of finished shoes, carton holding pressure, foam cycle compression, spring tension and compression and various dynamic and static cycle tests.

Related Products

-

Tension Testing Machine

IMADA Digital Force Gauge DST-1000N-High Precision-Suppier

Read moreRated 0 out of 5 -

Tension Testing Machine

YISIDA Digital Push Pull Gauge-DS2-2000N-High Precision

Read moreRated 0 out of 5 -

Tension Testing Machine

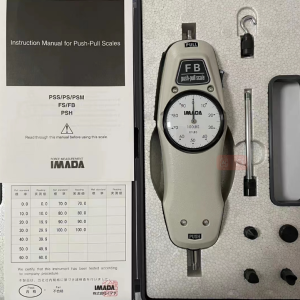

IMADA Mechanical Force Gauges FS-50k-High Precision

Read moreRated 0 out of 5 -

Tension Testing Machine

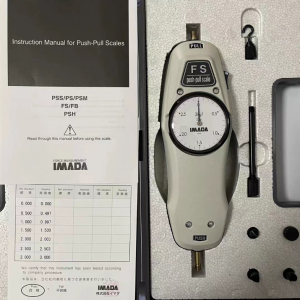

Imada Pointer Push-Pull Force Gauge FB-500N-High Precision

Read moreRated 0 out of 5 -

Tension Testing Machine

Pointer Push-Pull Gauge-Direct NK-500-Manufacturer

Read moreRated 0 out of 5 -

Tension Testing Machine

Four Point Bending Test Machine HTP-006-Manufacturer-HUST TONY

Read moreRated 0 out of 5 -

Tension Testing Machine

Universal Tensile Testing Machine HTP-150B-Supplier-HUST TONY

Read moreRated 0 out of 5