Battery Squeeze Needling Test Chamber HYZ-01-Supplier-HUST TONY

Battery Squeeze Needling Test Chamber

Battery Squeeze Needling Test Chamber,Battery extrusion needle punch testing machine is suitable for simulating all kinds of lithium metal batteries and lithium batteries, secondary cells or batteries containing alkaline or non-acid electrolytes, which are extruded and punctured during use, transportation, storage and waste disposal.

Youtube video :Click here

Trial Objective

1.This machine is suitable for simulating all kinds of batteries in the use, transportation, storage or treatment of household waste, the battery is squeezed and needled situation.

2.If the battery does not explode or catch fire, it is judged to be qualified.

Description of extrusion test methods

1.The test should be carried out at the ambient temperature of 20℃ soil and 5℃, the fully charged battery is placed in two planes, and the extrusion pressure of 13KN soil 0.78KN is perpendicular to the direction of the plate. Once the pressure is large and maximum, the extrusion test can be stopped.

2.If the battery does not have an external short circuit during the test, the battery under test is judged to be qualified if it does not explode or catch fire.

*For cylindrical batteries, the longitudinal axis of the extrusion battery should be parallel to the two plates of the extrusion device.

*For square and pouch cells, only the wide surface of the cell is subjected to a squeeze test.

*For coin-type or button-type batteries, the upper and lower planes of the battery are parallel to the flat plates for extrusion tests.

Description of acupuncture test methods

1.This machine is suitable for simulating the needling of all kinds of batteries in the process of transportation and storage.

2.The test should be carried out at an ambient temperature of 20℃±5℃. The battery connected with the thermocouple (the contact of the thermocouple is fixed on the large surface of the battery) is placed in the ventilator, and a rust-free steel needle with a diameter of 2-8mm is used to Pierce the central position of the largest surface of the battery at a speed of 10mm/s~40mm/s, and the test results are kept for any time. The battery does not explode or catch fire.

3.If the battery does not explode or catch fire, it is judged to be qualified.

Features

Technical Specifications

Model | HYZ-01 |

Extrusion Pressure Value | 1-20KN Adjustable |

Needling Force Value | 5Kn |

Screw Diameter | 32mm |

unit conversion | Kg,N,Lb |

Extrusion Speed | Commonly used 2mm per second, can be specified 1-15mm per second, adjustable |

Needling Speed | Commonly used 1-40mm per second adjustable, can be specified 0.1-80mm per second, adjustable |

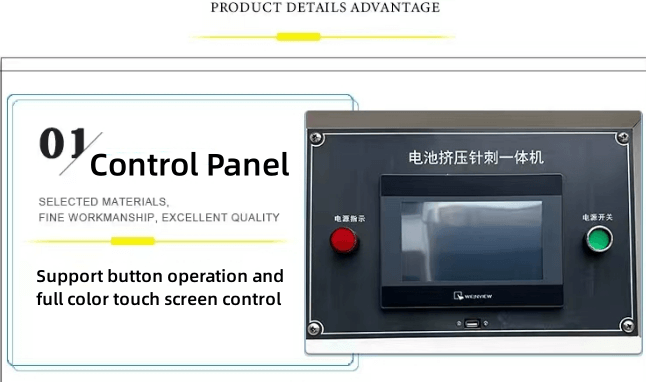

Force Display | Touch screen display,Have a historical record |

extrusion Head | Standard flat extrusion head, area: 20cm |

Needle Specification | φ3mm~φ8mm,Length :100mm |

Test Space | 300x300x300mm (L x W x H) |

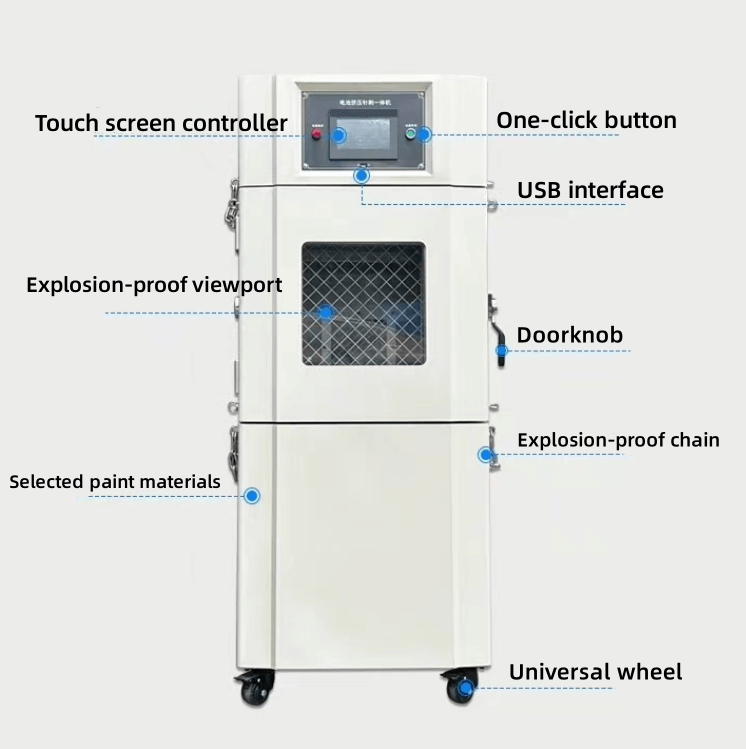

Inside Dimension | 500x600x750mm(L x W x H) |

External Dimension | 680*680*1815mm(L x W x H) |

Dimensions of the viewing window | 350mm*350mm With explosion-proof mesh 20mm explosion-proof glass |

Pressure Relief Opening | 230mm*230mm |

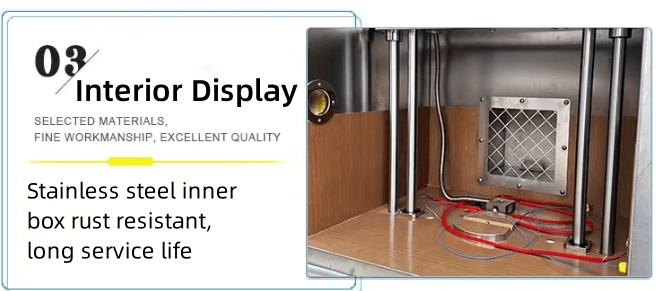

Box Material | Inner box 1.2mm thick stainless steel, outer box 1.5 cold plate electrostatic spraying |

Power Supply Power | 220V/50HZ/2.5KW |

Net Weight | About 300kg |

Dynamic Mode | Domestic servo motor. |

Type of Drive | Precision screw up and down movement |

Outer Box Type | Inner box and outer box combination, with four universal casters. |

Sensor | S-shaped pressure sensor |

Control Mode | PLC touch screen control. |

Blast resistant construction | The door is equipped with four explosion-proof chains, the box has a pressure relief door, and double toughened glass. |

Flue gas exhausting method | In-line, manual open, external reserved. |

Extrusion Method | The upper indenter is moving and the lower plane is fixed |

Data Export | USB |

Floodlight | 24V LED lights |

Standards

GB31241-2022 IEC62133-2012 UN38.3 UL1642-2005

Range of Application

This machine is suitable for simulating the needle puncture of various types of batteries during transportation and storage.

The test should be carried out at an ambient temperature of 20℃±5℃. The battery connected with the thermocouple (the contact of the thermocouple is fixed on the large surface of the battery) is placed in the ventilator, and a rust-free steel needle with a diameter of 2-8mm is used to Pierce the central position of the largest surface of the battery at a speed of 10mm/s~40mm/s, and the test results are kept for any time. The battery does not explode or catch fire.

If the battery does not explode or catch fire, it is judged to be qualified.

Related Products

-

Physical & Mechanical Testing

G92 Handheld Hall Gauss Meter-High Precision-Strict Quality

Read moreRated 0 out of 5 -

Toys safety testing equipment

Accessories of Assisting Tension & Pull Test

Read moreRated 0 out of 5 -

Physical & Mechanical Testing

Laboratory Fume Hoods TY-066-Chemical Exhaust Hood-Supplier

Read moreRated 0 out of 5 -

Toys safety testing equipment

Plastic Film Thickness Gauge TNF-011-High Precision-Supplier

Read moreRated 0 out of 5 -

Other Lab Testing Equipment

Tensile Strength Testing Equipment HTP-002-Single Arm-Computer Control-Supplier

Read moreRated 0 out of 5 -

Physical & Mechanical Testing

Tension Test Equipment HTP-001-Microcomputer Control-Single Arm

Read moreRated 0 out of 5 -

Other Lab Testing Equipment

Drying Oven DHG-9030A-Laboratory Drying Oven-Direct Manufacturer

Read moreRated 0 out of 5 -

Other Lab Testing Equipment

Salt Spray Tester TNJ-025-1-Corrosion Test-Manufacturer-HUST TONY

Read moreRated 0 out of 5